Why Underwater Welding Is Dangerous - Risks & Safety Tips

Last Updated: December 11, 2025

Why is underwater welding so dangerous? Learn about the real risks of underwater welding, including electric shock, explosions, drowning, and health problems. Understand how it works, safety measures, salary vs risk

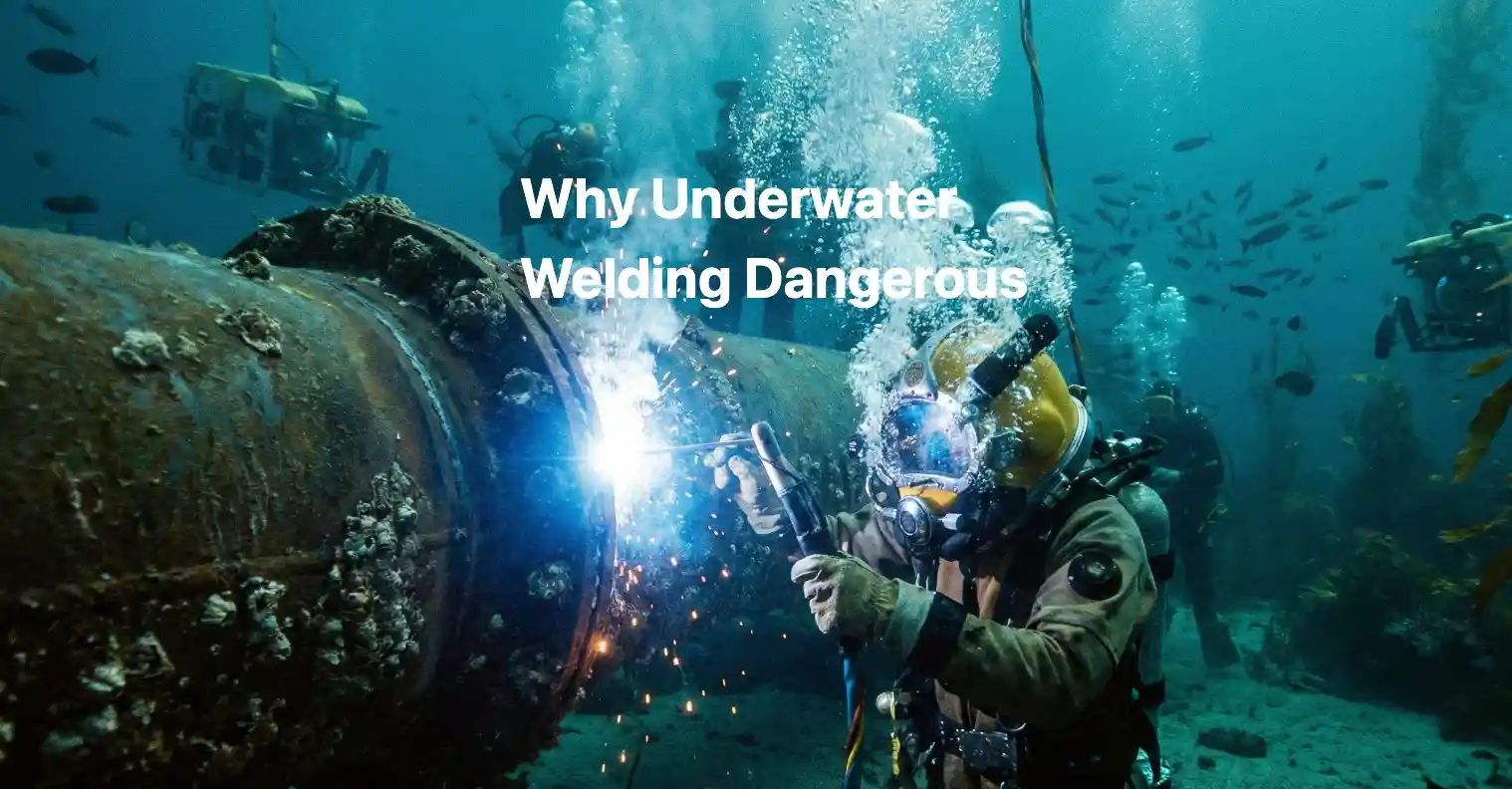

Underwater welding sounds exciting and high paying, but it is also known as one of the most dangerous jobs in the world. Many people hear about it on social media or YouTube and think, “This looks cool, I can earn a lot of money.” But before you decide anything, you must clearly understand why underwater welding is so risky.

In this blog, we will explain what underwater welding is, why it is so dangerous, the types of dangers, who should consider this career, safety measures and training. If you are planning a career in this field, or just curious, read this carefully till the end.

What Is Underwater Welding?

Underwater welding is the process of joining metal structures while being underwater. It is mainly used for ship repair and maintenance, oil and gas platforms, underwater pipelines, bridges, dams, and offshore structures. Most underwater welders are also commercial divers, trained in both diving and welding. They often work in deep water with dark conditions, cold temperatures, and strong currents, making the job physically and mentally tough.

There are two main types: wet welding, done directly in the water and fully exposed to the environment, and dry (hyperbaric) welding, where the welder works inside a special sealed chamber filled with gas at high pressure. Both have risks, but wet welding is generally considered more dangerous.

Why Is Underwater Welding So Dangerous?

Underwater welding combines three high-risk things in one job: water, electricity, and high pressure. Each is risky alone, but mixing them makes any small mistake life threatening.

1. Electric Shock Risk

Welding uses electricity to create intense heat and melt metal, but underwater, water conducts electricity if insulation or equipment fails from damaged cables, faulty gear, incorrect grounding, or human error. Even a small leak can be deadly, despite safety designs in diving systems and machines. Accidents still happen with poor maintenance or skipped procedures.

2. Explosions and Fire

Fire can happen underwater as welding produces gases like hydrogen and oxygen that form explosive pockets in confined spaces, ignited by sparks near flammable materials or without proper venting. These blasts can knock divers unconscious, damage helmets or suits, and cause serious injury or death, so planning, cleaning, and gas control are critical.

3. Drowning and Equipment Failure

Welders rely completely on diving gear to breathe and survive, failures like malfunctioning apparatus, damaged hoses, strong currents, poor visibility, or getting trapped turn fatal fast. Panic or delayed surface support heightens the danger, which is why training emphasizes calm procedures and team work.

4. Decompression Sickness

At depth, high pressure dissolves extra nitrogen into the blood surfacing too fast forms painful bubbles causing joint pain, dizziness, paralysis, or death. Welders avoid this with strict schedules, chambers, and no rushing skipping them risks lifelong issues. Even without accidents, long term health problems arise from constant noise and pressure leading to hearing loss, lung issues from compressed gases, joint and bone damage, plus stress and mental health strain. The body isn't built for repeated extreme conditions, shortening active careers.

5. Harsh Working Conditions

Expect cold water for long hours, zero visibility, rough seas, and remote sites far from family, leaving workers physically exhausted, mentally stressed, and emotionally drained. Fatigue boosts error risks.

6. High Responsibility and Human Error

Welders handle critical structures like oil rigs or bridges, a weak weld causes big failures later. Errors like skipping checks, ignoring rules, poor communication, or overconfidence have no margin for forgiveness one wrong move costs lives.

Is the High Salary Worth the Risk?

Many are drawn by the pay, as experienced welders earn far more than land based ones in some countries. But it comes with high training costs, physical and mental stress, injury or death risks, and shorter careers. Think long term, if it's just for money without passion for diving, welding, and extremes, it may not suit you.

Can Underwater Welding Be Made Safer?

Risks persist, but safety improves with proper commercial diving and welding certification, regular equipment checks, strict standards, team communication, pre dive planning, and modern gear. Reputable companies invest heavily, though the environment prevents 100% safety.

Who Should Consider Underwater Welding?

This suits those who love the ocean, handle deep water comfortably, stay physically fit and mentally strong, enjoy hands on technical work, remain calm under stress, and follow rules rigorously. Skip it if you fear depths, pressure, or confined spaces, or prefer low risk stability.

Frequently Asked Questions (FAQ)

1. Is underwater welding really the most dangerous job?

Yes, it's among the top due to deep water, electricity, explosions, and pressure. Modern gear helps, but risks remain high.

2. Can you die from underwater welding?

Yes, from shocks, drowning, bends, or explosions. Teams and procedures reduce risk, but it's never zero.

3. How deep do underwater welders go, and does depth increase danger?

30 to 300+ feet deeper means higher pressure, colder water, and more decompression risks.

4. Is underwater welding safe if you follow all the rules?

Safer, yes but unpredictable conditions keep it high risk.

5. How long is a typical underwater welding career?

5 to 10 years of intense work, then safer roles due to health toll.

6. What qualifications do you need to become an underwater welder?

Commercial diving cert, land welding skills, fitness, and specialized training.